Super Air Knife Replaces Fan Cooling

The Problem

A manufacturer of automotive electronics had a problem cooling computers as they exited a wave solder machine. In order to be handled and tested, the computers had to be first cooled to 27°C (81°F). Initially, they had tried banks of 6” (152mm) diameter axial fans across the 8-foot (2.5m) length of the cooling conveyor. It consisted of 16 fans blowing down from the top and 16 fans blowing up from the bottom at 7” (178mm) away from the surface. After travelling the full length of the conveyor with the fans running at full force (a five minute duration), the computers were still 42°C (108°F). Quality control personnel sat with an unacceptable backlog of computers waiting to be tested.

The Solution

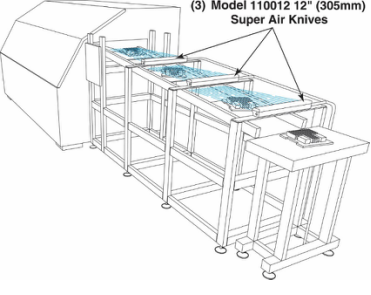

The company removed the top and bottom fan banks and replaced them with (3) Model 110012 12” (305mm) Super Air Knives that were evenly spaced across the cooling section. Each Super Air Knife was angled so the computer and heat sink received the constant rush of airflow. With the conveyor at the same speed 1.6 FPM (0.5m/min), and Super Air Knives at only 40 PSIG (2.8 BAR), the computers were cooled to 27°C (81°F) in 90 seconds!

Comment

The laminar airflow of the Super Air Knives was the key to success in this application. Fan cooling could only provide random spikes of air at moderate velocities. The uniform sheet of air from the Super Air Knife quietly swept the heat away within the first 2-foot (610mm) of the conveyor. Low air consumption and the compact size of the Super Air Knife were an added bonus.

Copyright 2019 © Compressed Air Australia | Website Design Web365 Darwin